2025-09-05

Turning, milling, drilling, grinding - a variety of CNC machining process analysis

Category: Technical knowledge

Category: News Fouse

Other Blogs

Contact Us

Sales manager:Jayzhou@yueyicnc.com

No. 365, Shachang 1st Road, Dalang Town, Dongguan City, Guangdong Province.

In the modern manufacturing industry, CNC machining technology is the core support, turning, milling, drilling and grinding of the four basic processes, each playing an irreplaceable role, and jointly promote the development of industrial production to high-precision and high-efficiency.

Lathe machining: precision shaping in rotation

Lathe machining through the spindle to drive the workpiece rotation, the tool along the parallel or perpendicular to the axis of rotation to do linear or curved motion to complete the cutting, as craftsmen carving rotating wooden blanks, can be accurately shaped rotating body surface.

Its characteristics are remarkable: high efficiency, can be continuous cutting of shafts, disc parts; stable accuracy, generally up to 0.01mm, precision lathe up to 0.001mm; adaptable, can be processed metal, plastic, wood and other materials.

Widely used, automobile manufacturing crankshaft, camshaft, machinery manufacturing drive shafts, screws, aerospace turbine shafts, missile bodies and other key parts processing are dependent on the lathe.

Modern CNC lathes are equipped with automatic feeding and tool magazine to achieve automatic loading and tool change, and advanced systems to support complex surface processing to meet the needs of diversified, high-precision parts.

II. Milling machine processing: multi-dimensional flexible cutting

Milling machine is different from lathe, the spindle drives the milling cutter to rotate, and the workpiece is fed along X, Y, Z axes to realise multi-face, multi-dimensional cutting, like a flexible dancer to process complex flat surfaces, curved surfaces, grooves and cavities.

There are many types of milling cutter, end milling cutter for processing plane, step, etc., face milling cutter is suitable for large plane machining, keyway milling cutter specialises in keyway, as well as shaping milling cutter, ball end milling cutter, etc. to meet the different machining needs.

It is characterised by high flexibility, wide machining range, can process simple surfaces and complex curved surfaces, and can also complete multiple processes such as drilling, boring, etc. to reduce clamping errors and improve accuracy.

It is widely used in mould manufacturing (cavity and core processing), aerospace (blade and magazine processing), automotive manufacturing (gearbox shell and cylinder block processing) and other fields.

CNC milling machines achieve automation through programming, improve efficiency and accuracy consistency, support four-axis and five-axis linkage processing of complex surfaces, high-end models are equipped with online inspection system, real-time monitoring and adjustment to ensure quality.

III. Drilling machine processing: accurate hole processing experts

The drilling machine uses a drill to process holes. The spindle drives the drill to rotate and feed downward, so that the drill cuts into the workpiece to form a hole, just like a precision shooter punching holes in a specified position.

Characterised by specialised hole machining, simple operation and high efficiency, it is suitable for processing through holes and blind holes in large quantities, but the precision is low (IT10-IT12 level), and high-precision holes need to be processed subsequently.

It is used in machinery manufacturing (bolt holes, oil holes), automobile manufacturing (cylinder block, cylinder head hole system), construction (steel structure connection holes), hardware (small hardware holes) and other industries.

CNC drilling machines are intelligent, programmed to automatically locate, drill and change tools. Multi-spindle models can process multiple holes at the same time, and complex hole systems can be processed by combining with CAD/CAM.

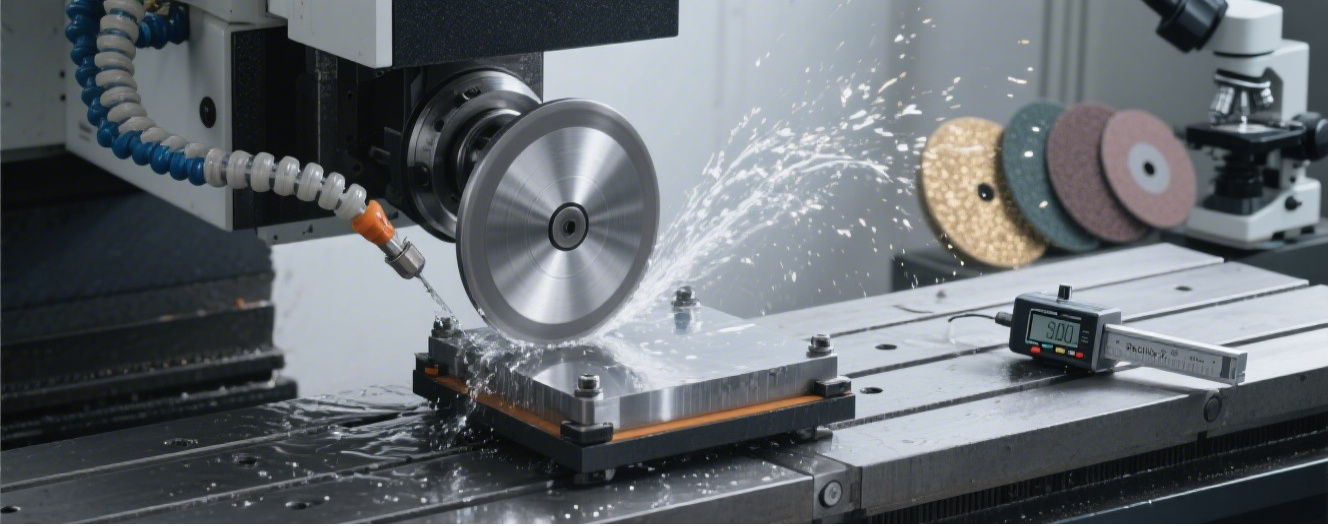

IV. Grinding Machines: Extreme Surface Finishing

Grinding machines use high-speed rotating wheels to grind the surface of the workpiece, and the abrasive grains cut to remove tiny bumps and defects, like a meticulous polisher to create a high-precision, polished surface.

The most important features are high precision (up to 0.0001mm), good surface quality (roughness as low as Ra0.025μm), and the ability to process hardened steel, cemented carbide, and other high hardness materials.

Mainly used in precision manufacturing field, bearing manufacturing processing raceway and rolling body, precision mould processing edge, cavity, aerospace processing blade, turbine disc, precision instrumentation parts surface grinding, etc..

CNC grinding machine through the programming of automated control of grinding, precise control parameters to ensure the consistency of precision, can automatically adjust the path and parameters to adapt to different needs, high-end models have online measurement compensation system to ensure processing quality.

To sum up, turning, milling, drilling and grinding cooperate with each other to form a complete parts processing system. With the progress of science and technology, they are more efficient, accurate, intelligent direction, providing strong technical support for modern industry, and promoting the manufacturing industry to a new height.

Let’s Build Something Great, Together

Yueyi Precision Technology (Guangdong) Co., Ltd

Sales manager:Jayzhou@yueyicnc.com

No. 365, Shachang 1st Road, Dalang Town, Dongguan City, Guangdong Province.

Follow Us

Copyright © 2025 Yueyi Precision Technology (Guangdong) Co., Ltd.